Immersion Research: Made In Hood River

John and Kara Weld started Immersion Research in a basement in 1997 with a sewing machine and an idea: to create high-quality, surf-inspired kayak apparel. At the time, there were few—if any—options for specialized paddling gear. Many kayakers were making their own boats and piecing together gear from other water sports. Fast forward to now and IR is making top of the line dry gear, spray skirts, and a fun line of apparel made right here in Hood River, Oregon.

Product development

What Is Made In Hood River?

Made In Hood River (MIHR) is a return to IR’s roots—designing and producing innovative kayak apparel from the ground up. The product team here works to create unique garments and accessories that could become the next big thing for paddling gear. Or a total experiment in fabrics that continue to ongoing development. You may already be familiar with their Hot Lap and Highwater Hoodies, two of MIHR’s early success stories.

Sewing room after a long day of work

Innovation at it's Core

One of MIHR’s biggest strengths is its ability to innovate. At first glance, the Hood River storefront might look like just another retail shop. Once you step inside you’ll find a mini factory. With in-house experts in fabric, sewing, and product development, IR can test and refine gear in near real-time. Prototypes can be created quickly and undergo rigorous field testing. When modifications are needed, it can happen swiftly and sent back out for further testing.

Overcoming Challenges

Bringing new products to market is a huge challenge in itself. While it would be fun to always just make whatever comes to mind there has to be someone paying attention to cost, profit, and what is actually going to sell.

Scraps and small bits

"There are a handful of things that we thought would be big sellers just flop. There have also been a few items that just really took off." Whitney, IR Product Developer

Another major challenge is sourcing the right fabrics. MIHR gear is made from end rolls of fabric, which helps reduces costs while also promoting sustainability. This also dictates color options, sizes, and quantity. So if you see something you like, especially in a specific color, you should buy it as the color may never come back.

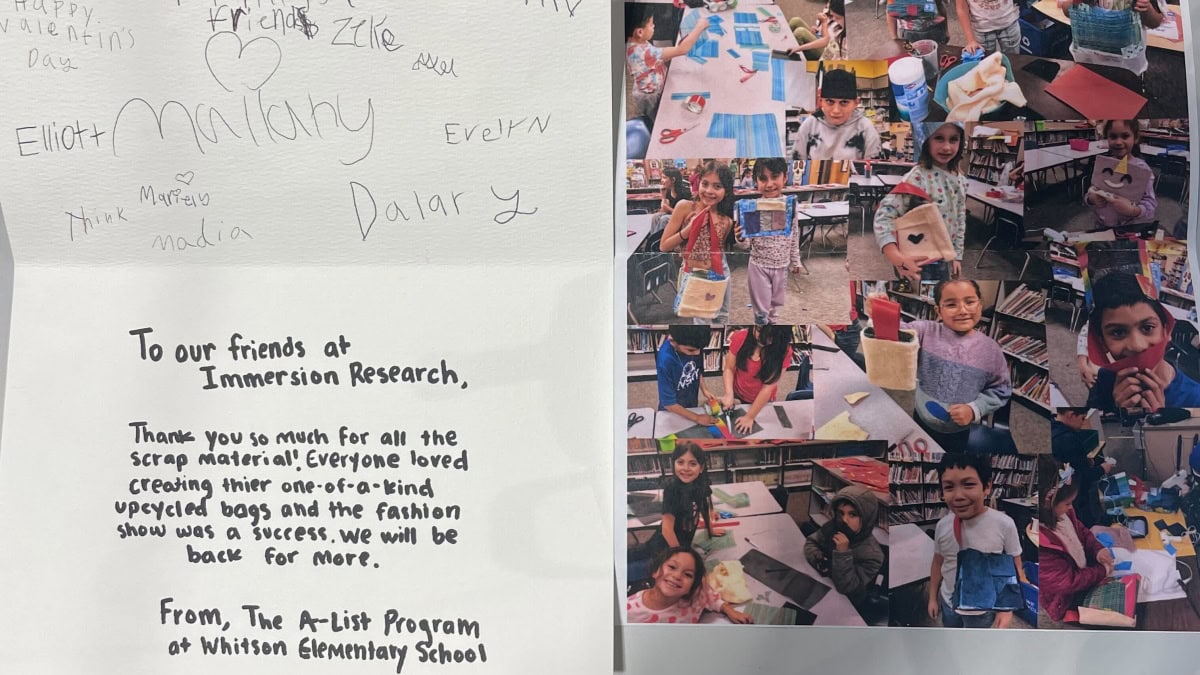

IR is committed to reducing waste and reusing materials when possible. However fabric recycling remains a challenge. Right now the option is a huge bin of small scraps free for anyone. IR donates scraps to Whitson Elementary (White Salmon Elementary School) and the kids made a ton of creations with them, bags, hats, etc. Also if you're looking for stuffing for a dog bed or scraps for a creative project, check the scrap bin.

Craft time with Whitson Elementary

Looking Ahead

MIHR is more than just a manufacturing initiative—it’s a way to bring production back in-house, experiment freely, and develop gear that paddlers are passionate about. The ability to test new products immediately, with athletes of all skill levels in real-world conditions, makes this process unique. Whether it's a casual paddler or an expedition kayaker, MIHR ensures that new designs meet the highest performance standards.

This mini factory allows IR to produce small batches, refine products, and ultimately create the best gear possible. John and Kara’s vision has always been to push the limits of innovation, and MIHR is a key part of that mission.

New Gear on the Horizon

With new fabric developments and better sourcing, there is so much room to create. In a given year there are upwards of 50 solid ideas that get a start with just a few making their way to the shelves. The most recent pieces have been the Lariat Throw Bag and Waste Belt, Nanowave Handwarmers, Alpha Hoodie, and hearty gear bags and fun totes.

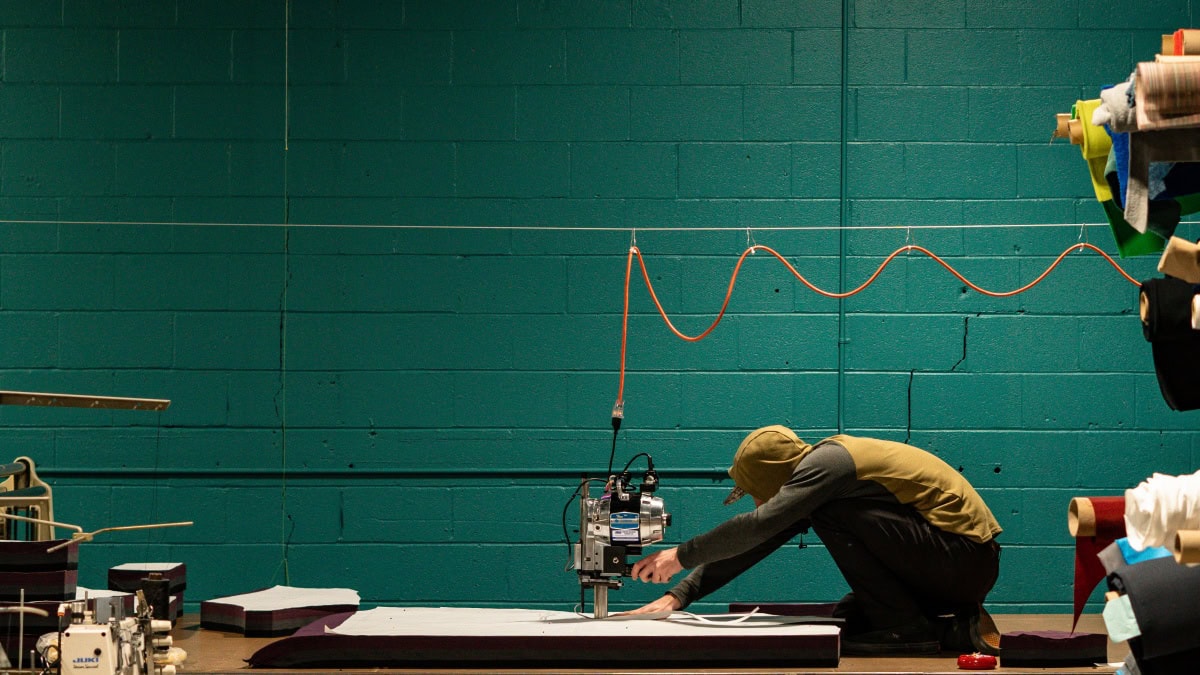

Wyatt cutting fabric

One big project that is now on the main stage for the brand of IR, is a specially designed line of dry suits for Search and Rescue communities." Prototypes were built, tested, and reworked completely in-house until it was ready for a full production run to serve this industry. It's knocking on a 3 year process with more design innovations already slated for production in the coming year.

Made In Hood River is more than just a collection of products—it’s a testament to the creativity, passion, and craftsmanship that define Immersion Research. Stop by, see the innovation in action, and maybe get your hands on some one of a kind paddling gear.